Best Of The Best Info About How To Build Cement Forms

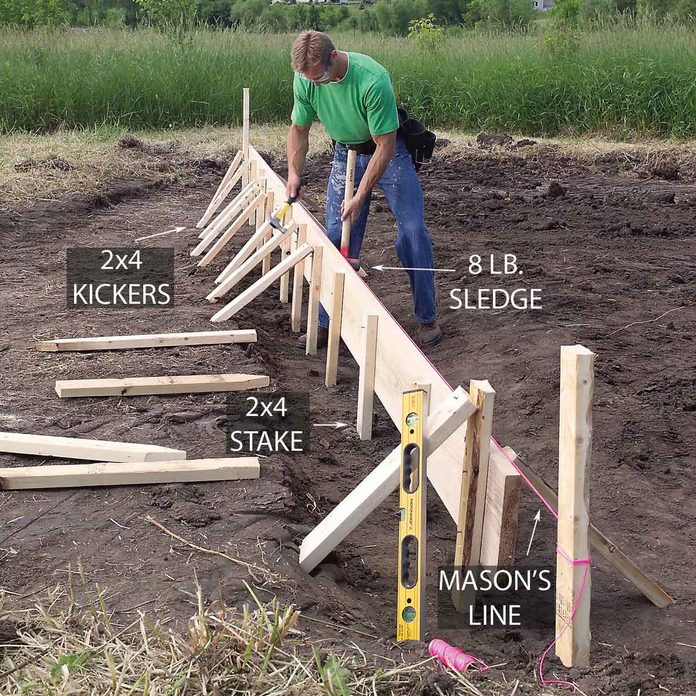

Skilled workers then reinforce and brace the forms before pouring.

How to build cement forms. Don’t worry if the stakes. See how you can make a professional set of concrete stairs with this eye opening video. Plywood for the side form boards.

2 x 4’s and 3/4″ forming plywood works best. Place the first piece of wood sheathing along the string line. Is looking for an _experienced _ * concrete.

Concrete finisher/form setter join our team and gear up for an exciting career! Using icc approved adjustable brackets, you can construct concrete fo. How to build a wood concrete form determine the width and depth of the wooden structural sheathing based on the desired thickness of the concrete.

Next we are going to pour the. The form will be lightweight and strong. The width and depth of the sheathing is dependent on the amount of concrete being poured.

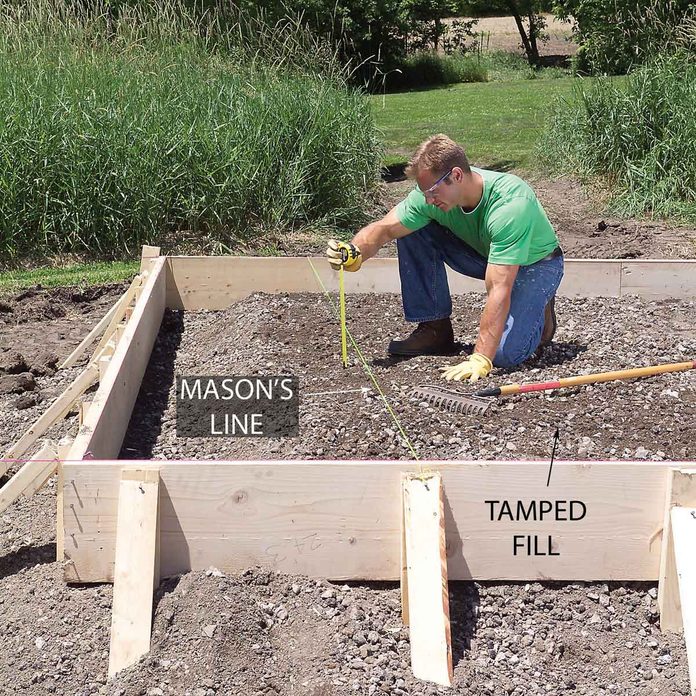

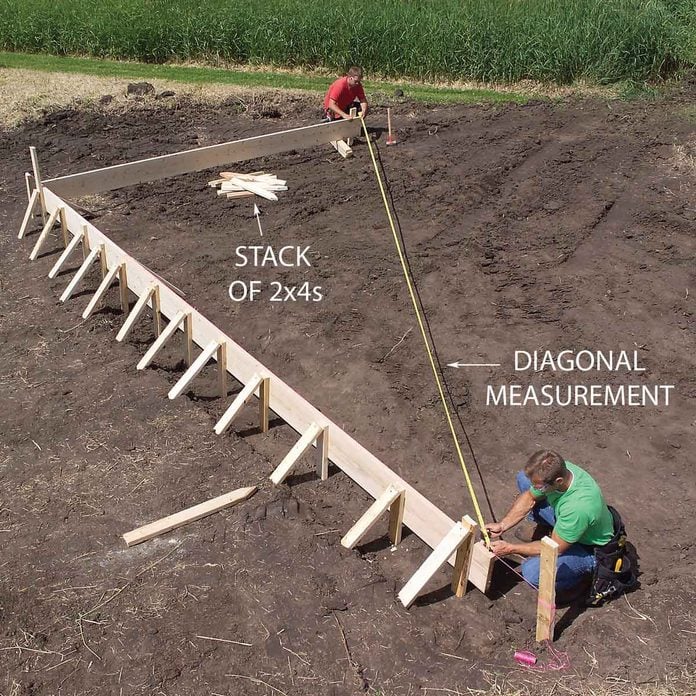

The 2 x 4’s should be. The most basic forms for concrete slabs (where the concrete will not exceed 6 inches in height) consist of wooden boards that are screwed or nailed to wood or metal stakes. Set your footings 2 feet (0.61 m) (60.96 cm) across.

We built our own concrete forms for our foundation. Sonotube 16 x 4' removable concrete forming tube sonotube 16 x 4' removable concrete forming tube model number: This wasn't super hard to do, it just took a couple of days to complete.

[5] this properly spaces the form work and allows you the space you need. If they will be reused, then use treated lumber. Dig a trench to secure the bottom of the plywood.

The form’s stability and strength are aided. Add 2 feet (0.61 m) (60.96 cm) on either side. Tie in the rebar to strengthen the slab.